Service on site

Hydrau Constructie is well known for it’s a reliable and fast service. This is carried out in our workshop in The Hague or at any other location. Our mechanics use well utilized mobile workshops to make sure that almost every repair can be executed on site. This repair can vary from a hydraulic hose repair to the replacement of hydraulic components. Our service trailer is equipped with a hose press with which hoses can be produced on site.

Service in our workshop

There is also the possibility to execute the work in our workshop. We can do all sorts of hydraulic repair in our workshop. This may vary from the replacement of hoses, piping, couplings or hydraulic components. Our workshop is equipped with a very large amount of various tools to carry out all types of repairs. We also repair and test hydraulic cylinders of all sizes. Through close cooperation with a specialized manufacturer of hydraulic cylinders, we can carry out extensive repairs on cylinders within a short period of time. These types of repairs go far beyond just replacing the seals. If, for example, the rod, piston or cylinder head is defective or worn, we can draw and produce the parts as if they were new. We have developed a disassembly bench which we use for cylinders which are difficult to open. We can generate a torque of over 100,000 Nm with the disassembly bench. In case of repairs, we will be in contact whether it is cheaper and easier to repair the cylinder or to supply a new one.

Maintenance

It is advisable to carry out periodic maintenance on your machines to prevent unscheduled and unwanted downtime. By periodic maintenance we understand, among others, the following things:

Check or replace hydraulic fluids

Replacement of filters

Check for leaks

Assess the condition of the hydraulic hoses and replace them if necessary

Replacement of seals

Overhaul

We overhaul hydraulic components on a daily basis to extend the lifespan. This can be a hydraulic valve, cylinder or a complete hydraulic power pack. After disassembly, all seals and defective components are replaced and everything is properly cleaned. When we’ve assembled everything back together we will test and conserve the component.

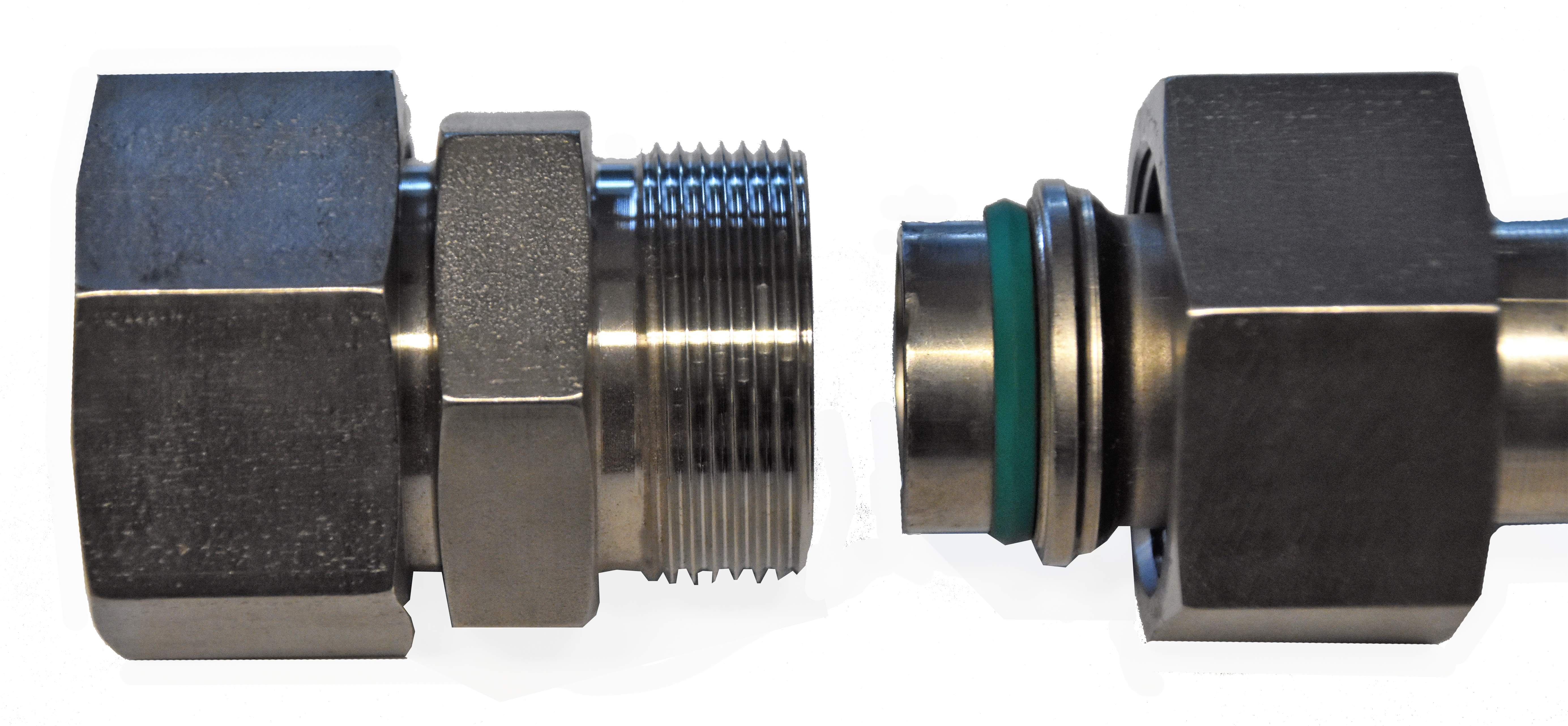

Walform+

Walform+ is the preferred method to create a reliable connection between steel and stainless steel pipes. Standard L and S series cutting ring couplings are used, however the cutting ring on the pipe is replaced by a form-fitting connection with Viton seal ring. The pipe end is pushed into the machine and this forms the shape of a cutting ring. This avoids the weakest link of the connection, which is the cutting ring itself. In addition, it also offers advantages for the assembly, especially when stainless steel pipes are used. The mounting force of the coupling is reduced enormously because the cutting ring doesn’t have to cut into the pipe. As a result, the chance of damaged threads on the stainless steel couplings is much smaller. Walform+ has a type approval for all common ship inspection agencies!

We have access to our own Walform+ machine which can also be used on site. This results in the Walform+ machine being interesting for smaller project too. Please contact us if you are interested.